रिफ्रैक्टरी बॉल का उपयोग क्या है?

Nov 23, 2024आग रोक गेंदें उच्च तापमान वाले औद्योगिक अनुप्रयोगों में महत्वपूर्ण भूमिका निभाती हैं, विशेष रूप से ऐसे वातावरण में जहां गर्मी, घिसाव और रासायनिक संक्षारण के लिए असाधारण प्रतिरोध की आवश्यकता होती है। ये गेंदें, आमतौर पर मैग्नीशियम एल्यूमीनियम स्पिनल जैसी उच्च गुणवत्ता वाली सामग्री से बनाई जाती हैं, चरम स्थितियों में स्थायित्व और प्रदर्शन के लिए इंजीनियर की जाती हैं। यह लेख दुर्दम्य गेंदों के उपयोग, उनके लाभों और वे विभिन्न उद्योगों में अपरिहार्य क्यों हैं, इसकी पड़ताल करता है।

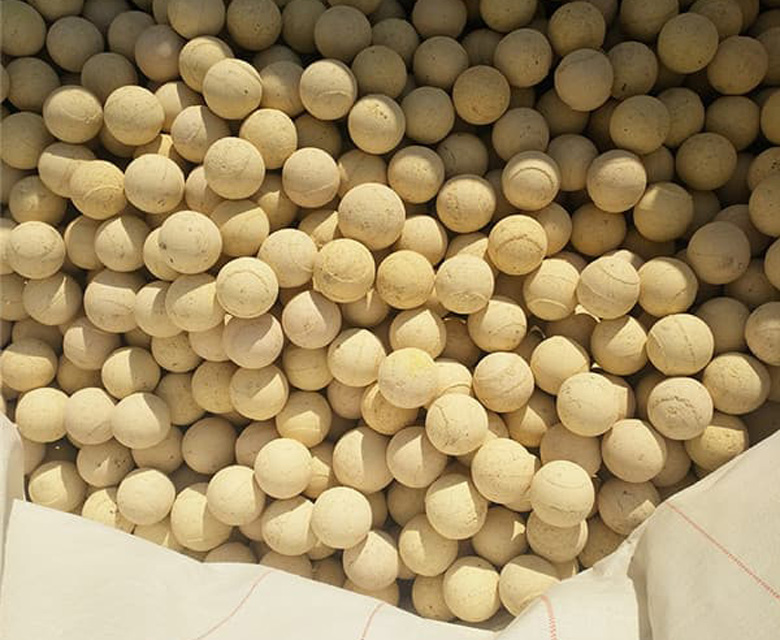

आग रोक गेंदें गोलाकार, गर्मी प्रतिरोधी सामग्री हैं जिन्हें उन अनुप्रयोगों के लिए डिज़ाइन किया गया है जहां उच्च तापमान, रासायनिक स्थिरता और यांत्रिक शक्ति आवश्यक है। ये गेंदें आम तौर पर अपने प्रदर्शन को बढ़ाने के लिए कच्चे माल जैसे एल्यूमिना, मैग्नीशिया या अन्य ऑक्साइड के साथ इनके संयोजन से बनाई जाती हैं।

विनिर्माण प्रक्रिया में कच्चे माल को एक गेंद के रूप में आकार देना शामिल है, जिसके बाद आवश्यक घनत्व और ताकत प्राप्त करने के लिए उच्च तापमान पर सिंटरिंग या फायरिंग की जाती है। परिणाम एक टिकाऊ, तापीय रूप से स्थिर उत्पाद है जो तीव्र परिचालन स्थितियों का सामना कर सकता है।

आग रोक गेंदें बहुमुखी हैं और विभिन्न औद्योगिक अनुप्रयोगों में कई कार्य करती हैं:

रिएक्टरों में उत्प्रेरक समर्थन

रासायनिक रिएक्टरों में समर्थन मीडिया के रूप में दुर्दम्य गेंदों का व्यापक रूप से उपयोग किया जाता है। वे रिएक्टरों के भीतर उच्च तापमान और संक्षारक वातावरण का सामना करते हुए उत्प्रेरक के लिए एक स्थिर सतह प्रदान करते हैं। उनका समान आकार रासायनिक प्रतिक्रियाओं को अनुकूलित करते हुए, गैस और तरल प्रवाह वितरण को भी सुनिश्चित करता है।

ताप भंडारण और स्थानांतरण

ये गेंदें थर्मल स्टोरेज सिस्टम में प्रभावी हैं जहां गर्मी अवशोषण और रिलीज महत्वपूर्ण हैं। उदाहरण के लिए, पुनर्योजी बर्नर में, दुर्दम्य गेंदें ऊर्जा संरक्षण और लगातार प्रदर्शन सुनिश्चित करते हुए गर्मी को कुशलतापूर्वक संग्रहित और स्थानांतरित करने में मदद करती हैं।

फर्नेस लाइनिंग्स की सुरक्षा करना

आग रोक गेंदों का उपयोग औद्योगिक भट्टियों के अस्तर की सुरक्षा के लिए किया जाता है, विशेष रूप से स्टील, कांच और सिरेमिक उद्योगों में। रासायनिक हमले और थर्मल शॉक के प्रति उनका प्रतिरोध भट्ठी के अस्तर पर टूट-फूट को कम करता है, रखरखाव लागत और डाउनटाइम को कम करता है।

गैस शोधन प्रणाली

उन प्रणालियों में जो औद्योगिक गैसों से अशुद्धियाँ हटाती हैं, दुर्दम्य गेंदें फ़िल्टरिंग माध्यम के रूप में कार्य करती हैं। उनकी उच्च सरंध्रता और रासायनिक संक्षारण के प्रति प्रतिरोध उन्हें कणों और अन्य प्रदूषकों को प्रभावी ढंग से फंसाने के लिए उपयुक्त बनाता है।

द्रवीकृत बिस्तर बॉयलर

बिजली उत्पादन में, द्रवीकृत बिस्तर बॉयलरों में दुर्दम्य गेंदों का उपयोग किया जाता है। वे एक स्थिर, गर्मी प्रतिरोधी माध्यम प्रदान करके दहन प्रक्रिया को बढ़ाते हैं जो कुशल ईंधन जलने का समर्थन करता है और उत्सर्जन को कम करता है।

सिरेमिक उद्योग में भट्ठा फर्नीचर

आग रोक गेंदों का उपयोग सिरेमिक उद्योग में भट्ठी फर्नीचर के रूप में भी किया जाता है, जो फायरिंग के दौरान उत्पादों का समर्थन करता है। वे विरूपण और थर्मल क्षति का विरोध करते हैं, लगातार फायरिंग गुणवत्ता सुनिश्चित करते हैं और भट्ठा जीवन का विस्तार करते हैं।

कई उद्योग अपने संचालन के लिए दुर्दम्य गेंदों पर निर्भर हैं, जिनमें शामिल हैं:

डीवाईसेन औद्योगिक औद्योगिक अनुप्रयोगों की मांग के लिए तैयार उच्च गुणवत्ता वाले मैग्नीशियम एल्यूमीनियम दुर्दम्य आग गेंदों की पेशकश करता है। हमारी दुर्दम्य गेंदों को अधिकतम प्रदर्शन के लिए इंजीनियर किया गया है, जिसमें बेहतर थर्मल प्रतिरोध, रासायनिक स्थिरता और यांत्रिक स्थायित्व शामिल है।

गुणवत्ता और विश्वसनीयता के प्रति प्रतिबद्धता के साथ, DYSen सुनिश्चित करता है कि हमारे उत्पाद उच्चतम मानकों को पूरा करते हैं। चाहे आपको थर्मल स्टोरेज, रिएक्टर सपोर्ट, या फर्नेस लाइनिंग के लिए रिफ्रैक्टरी बॉल्स की आवश्यकता हो, हम आपके संचालन को अनुकूलित करने के लिए डिज़ाइन किए गए समाधान प्रदान करते हैं।

आग रोक गेंदें उन उद्योगों में अपरिहार्य हैं जो उच्च तापमान प्रतिरोध, रासायनिक स्थिरता और यांत्रिक शक्ति की मांग करते हैं। रासायनिक रिएक्टरों में सहायक उत्प्रेरक से लेकर भट्टियों में थर्मल भंडारण बढ़ाने तक, उनके अनुप्रयोग विविध और महत्वपूर्ण हैं। उच्च गुणवत्ता वाली रिफ्रैक्टरी गेंदों का चयन, जैसे कि डीवाईसेन इंडस्ट्रियल द्वारा पेश की जाती है, लंबे समय तक चलने वाले प्रदर्शन और परिचालन दक्षता को सुनिश्चित करती है।

विश्वसनीय रिफ्रैक्टरी समाधानों में निवेश करने से न केवल डाउनटाइम कम होता है, बल्कि उत्पादकता भी बढ़ती है, जिससे रिफ्रैक्टरी बॉल्स अत्यधिक परिस्थितियों में काम करने वाले उद्योगों के लिए एक स्मार्ट विकल्प बन जाता है।

Tags :