बॉल बियरिंग्स कक्षा 8 क्या हैं?

Oct 16, 2024मशीनरी और उपकरणों की एक विस्तृत श्रृंखला में बॉल बेयरिंग एक आवश्यक घटक है, जो सुचारू गति प्रदान करता है और गतिशील भागों के बीच घर्षण को कम करता है। वे विभिन्न यांत्रिक प्रणालियों की दक्षता, स्थायित्व और प्रदर्शन सुनिश्चित करने में महत्वपूर्ण भूमिका निभाते हैं। बॉल बेयरिंग के विभिन्न वर्गीकरणों में से, कक्षा 8 बॉल बेयरिंग को विशेष रूप से औद्योगिक अनुप्रयोगों की उच्च-प्रदर्शन आवश्यकताओं को पूरा करने के लिए डिज़ाइन किया गया है। यह लेख यह पता लगाएगा कि कक्षा 8 बॉल बेयरिंग, उनके अनुप्रयोगों को क्या परिभाषित करता है, और वे भारी औद्योगिक क्षेत्रों के लिए महत्वपूर्ण क्यों हैं।

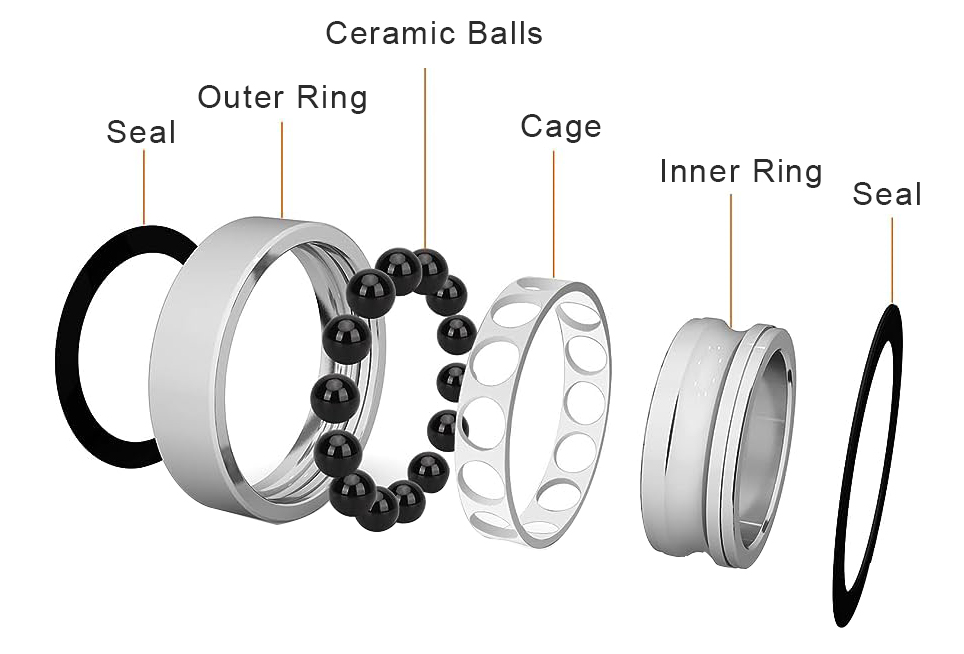

कक्षा 8 बॉल बेयरिंग भारी भार, उच्च गति और चरम स्थितियों को संभालने के लिए डिज़ाइन किए गए उच्च-सटीक बीयरिंग की श्रेणी से संबंधित हैं। बियरिंग्स को आम तौर पर अंतर्राष्ट्रीय मानकीकरण संगठन (आईएसओ) या अमेरिकी राष्ट्रीय मानक संस्थान (एएनएसआई) जैसे संगठनों द्वारा निर्धारित सटीकता, सहनशीलता और प्रदर्शन मानकों के अनुसार वर्गीकृत किया जाता है।

सहनशीलता और परिशुद्धता: कक्षा 8 बॉल बेयरिंग उच्च परिशुद्धता के साथ निर्मित होते हैं, जिनमें निम्न-श्रेणी के बीयरिंगों की तुलना में सख्त सहनशीलता होती है। यह सटीकता सुनिश्चित करती है कि वे प्रदर्शन से समझौता किए बिना भारी भार के तहत और उच्च घूर्णी गति पर काम कर सकते हैं।

सहनशीलता: स्टील या सिरेमिक जैसी मजबूत सामग्रियों से निर्मित, क्लास 8 बॉल बेयरिंग को भारी उद्योग के मांग वाले वातावरण का सामना करने के लिए डिज़ाइन किया गया है। ये सामग्रियां पहनने, गर्मी और संक्षारण के लिए उत्कृष्ट प्रतिरोध प्रदान करती हैं, जिससे बीयरिंग की लंबी उम्र सुनिश्चित होती है।

क्लास 8 बॉल बेयरिंग का उपयोग उद्योगों और अनुप्रयोगों की एक विस्तृत श्रृंखला में किया जाता है, खासकर जहां उच्च परिशुद्धता, स्थायित्व और विश्वसनीयता महत्वपूर्ण होती है। कुछ प्राथमिक अनुप्रयोगों में शामिल हैं:

मोटर वाहन उद्योग: ऑटोमोटिव विनिर्माण में, क्लास 8 बॉल बेयरिंग का उपयोग इंजन, ट्रांसमिशन और डिफरेंशियल जैसे महत्वपूर्ण घटकों में किया जाता है। वे सुचारू, घर्षण रहित गति सुनिश्चित करते हैं, जो वाहन के प्रदर्शन, ईंधन दक्षता और दीर्घायु में सुधार के लिए आवश्यक है।

औद्योगिक मशीनरी: भारी मशीनरी, जैसे कि खनन, धातु और निर्माण में उपयोग की जाने वाली मशीनें, तीव्र भार की मांग और कठोर परिचालन स्थितियों को संभालने के लिए कक्षा 8 बॉल बेयरिंग पर निर्भर करती हैं। ये बीयरिंग कन्वेयर सिस्टम, क्रशर और बड़े घूमने वाले उपकरणों के सुचारू संचालन में योगदान करते हैं।

एयरोस्पेस: एयरोस्पेस अनुप्रयोगों में, परिशुद्धता और स्थायित्व सर्वोपरि है। क्लास 8 बॉल बेयरिंग का उपयोग आमतौर पर विमान के इंजन, लैंडिंग गियर और नियंत्रण प्रणालियों में किया जाता है, जहां वे घर्षण को कम करने में मदद करते हैं और चरम स्थितियों में विश्वसनीय प्रदर्शन सुनिश्चित करते हैं।

ऊर्जा क्षेत्र: ऊर्जा उद्योग में, पवन टरबाइन से लेकर बिजली संयंत्रों तक, क्लास 8 बॉल बेयरिंग टर्बाइन और जनरेटर जैसे बड़े घूमने वाले उपकरणों का समर्थन करते हैं। उनकी उच्च भार वहन क्षमता और स्थायित्व उन्हें महत्वपूर्ण ऊर्जा बुनियादी ढांचे में परिचालन दक्षता बनाए रखने के लिए आदर्श बनाती है।

क्लास 8 बॉल बेयरिंग की सटीकता और स्थायित्व कई फायदे प्रदान करती है जो उन्हें कई उद्योगों में अपरिहार्य बनाती है। कुछ प्रमुख लाभों में शामिल हैं:

घर्षण में कमी: गतिशील भागों के बीच घर्षण को कम करके, कक्षा 8 बॉल बेयरिंग यांत्रिक प्रणालियों की दक्षता में सुधार करती है, जिसके परिणामस्वरूप सुचारू संचालन, घटकों पर कम घिसाव और कम ऊर्जा खपत होती है।

उच्च भार क्षमता: इन बीयरिंगों को महत्वपूर्ण अक्षीय और रेडियल भार का समर्थन करने के लिए डिज़ाइन किया गया है, जो उन्हें उन अनुप्रयोगों के लिए उपयुक्त बनाता है जहां भारी भार और उच्च तनाव आम हैं।

बढ़ी हुई स्थायित्व: कक्षा 8 बॉल बेयरिंग बनाने के लिए उपयोग की जाने वाली सामग्री और विनिर्माण प्रक्रियाएं यह सुनिश्चित करती हैं कि वे उच्च तापमान, भारी भार और संक्षारक वातावरण सहित चरम स्थितियों का सामना कर सकें।

परिशुद्धता और स्थिरता: क्लास 8 बियरिंग उच्च स्तर की परिशुद्धता प्रदान करते हैं, जो मशीनरी और उपकरणों के संचालन में बेहतर सटीकता और स्थिरता में तब्दील हो जाती है। एयरोस्पेस जैसे उद्योगों में यह सटीकता महत्वपूर्ण है, जहां थोड़े से विचलन के भी गंभीर परिणाम हो सकते हैं।

पर DYSen औद्योगिक, हम औद्योगिक अनुप्रयोगों के लिए उच्च गुणवत्ता वाले बॉल बेयरिंग के महत्व को समझते हैं। क्लास 8 बॉल बेयरिंग का हमारा चयन ऑटोमोटिव, एयरोस्पेस और भारी मशीनरी उद्योगों सहित विभिन्न क्षेत्रों की मांग को पूरा करने के लिए डिज़ाइन किया गया है। हम अपने ग्राहकों को विश्वसनीय, उच्च-प्रदर्शन समाधान प्रदान करने के लिए एसकेएफ, आईएनए, एफएजी, टिमकेन, एनएसके और अन्य अग्रणी निर्माताओं के साथ साझेदारी करते हैं।

हम बॉल बेयरिंग प्रदान करते हैं जो आपकी विशिष्ट आवश्यकताओं के अनुरूप होते हैं, यह सुनिश्चित करते हुए कि आपको अपने आवेदन के लिए सही उत्पाद प्राप्त हो। हमारी पेशेवर अंतर्राष्ट्रीय व्यापार टीम और एक मजबूत आपूर्ति श्रृंखला के साथ, हम समय पर डिलीवरी और उत्कृष्ट ग्राहक सेवा सुनिश्चित करते हैं।

कक्षा 8 बॉल बेयरिंग कई औद्योगिक अनुप्रयोगों के सुचारू संचालन के लिए महत्वपूर्ण हैं। उनकी सटीकता, स्थायित्व और उच्च भार-वहन क्षमता उन्हें मांग वाले वातावरण के लिए पसंदीदा विकल्प बनाती है। चाहे आप ऑटोमोटिव, एयरोस्पेस, या भारी मशीनरी उद्योग में हों, सही बॉल बेयरिंग चुनने से आपके संचालन की दक्षता और विश्वसनीयता पर महत्वपूर्ण प्रभाव पड़ सकता है।

डीवाईसेन इंडस्ट्रियल में, हम उच्च गुणवत्ता वाले बॉल बेयरिंग प्रदान करने के लिए प्रतिबद्ध हैं जो यह सुनिश्चित करते हैं कि आपका सिस्टम चरम प्रदर्शन पर काम करे। हमारे उत्पादों की विस्तृत श्रृंखला का अन्वेषण करें और अपनी औद्योगिक आवश्यकताओं के लिए सही समाधान खोजें।

Tags :