एल्यूमिना ईंटों का उपयोग किस लिए किया जाता है?

Oct 30, 2024जब भारी औद्योगिक क्षेत्र में उच्च प्रदर्शन वाली सामग्रियों की बात आती है, बुलबुला एल्युमिना अग्नि ईंटें अपने असाधारण तापीय गुणों और संरचनात्मक अखंडता के लिए खड़े रहें। ये ईंटें विभिन्न अनुप्रयोगों के लिए आवश्यक हैं, विशेष रूप से भट्टियों, भट्टियों और भस्मक जैसे उच्च तापमान वाले वातावरण में। यह लेख बताता है कि बुलबुला एल्यूमिना अग्नि ईंटें क्या हैं, उनके लाभ, अनुप्रयोग और वे पारंपरिक मिट्टी इन्सुलेशन ईंटों से कैसे तुलना करते हैं।

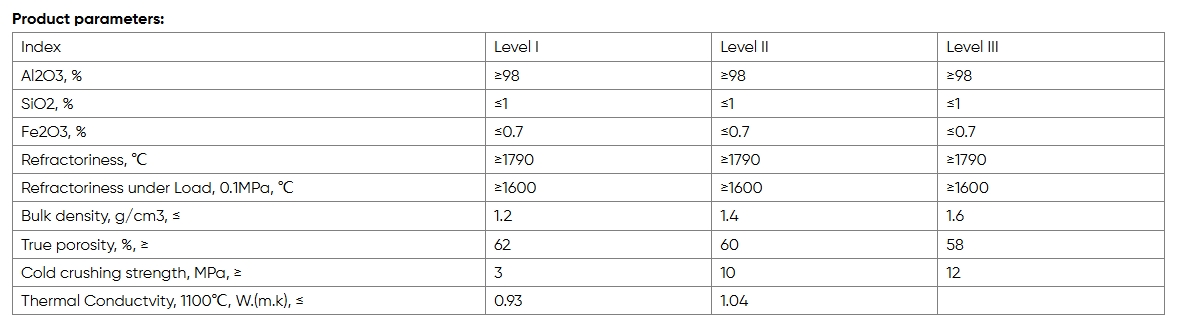

बबल एल्यूमिना फायर ईंटें उच्च शुद्धता वाले एल्यूमिना से बनी विशेष दुर्दम्य सामग्री हैं। उनकी विशेषता उनकी अद्वितीय सेलुलर संरचना है, जिसमें कई छोटे बुलबुले होते हैं। यह संरचना मजबूती और स्थायित्व बनाए रखते हुए उनके इन्सुलेशन गुणों को बढ़ाती है। बुलबुला एल्यूमिना ईंटों का प्राथमिक लाभ उनकी अत्यधिक तापमान को बिना ख़राब हुए झेलने की क्षमता है, जो उन्हें मांग वाले औद्योगिक वातावरण के लिए आदर्श बनाता है।

उच्च तापीय प्रतिरोध: बबल एल्यूमिना फायर ईंटें 1,600°C (2,912°F) से अधिक तापमान सहन कर सकती हैं। उच्च ताप के तहत संरचनात्मक अखंडता बनाए रखने की उनकी क्षमता उन्हें भट्टियों और भट्टियों में उपयोग के लिए उपयुक्त बनाती है।

उत्कृष्ट इन्सुलेशन गुण: बबल एल्यूमिना ईंटों की सेलुलर संरचना बेहतर इन्सुलेशन प्रदान करती है, गर्मी के नुकसान को कम करती है और थर्मल अनुप्रयोगों में ऊर्जा दक्षता में सुधार करती है। यह सुविधा औद्योगिक सेटिंग्स में विशेष रूप से फायदेमंद है जहां तापमान नियंत्रण महत्वपूर्ण है।

कम तापीय चालकता: ये ईंटें कम तापीय चालकता प्रदर्शित करती हैं, जिसका अर्थ है कि वे प्रभावी ढंग से गर्मी हस्तांतरण का विरोध कर सकती हैं। यह संपत्ति ऊर्जा खपत को कम करने में मदद करती है, जिससे औद्योगिक संचालन में लागत बचत होती है।

हल्की रचना: पारंपरिक मिट्टी इन्सुलेशन ईंटों की तुलना में, बबल एल्यूमिना फायर ईंटें हल्की होती हैं, जिससे उन्हें संभालना और स्थापित करना आसान हो जाता है। यह सुविधा श्रम लागत और स्थापना समय को काफी कम कर सकती है।

रासायनिक स्थिरता: बबल एल्यूमिना फायर ईंटें विभिन्न रसायनों और वातावरणों के प्रति प्रतिरोधी हैं, जो मांग वाले अनुप्रयोगों में दीर्घायु और स्थायित्व सुनिश्चित करती हैं। वे कई संक्षारक पदार्थों पर प्रतिकूल प्रतिक्रिया नहीं करते हैं, जो उन्हें रासायनिक प्रसंस्करण उद्योगों में उपयोग के लिए आदर्श बनाता है।

बबल एल्यूमिना फायर ब्रिक्स का उपयोग उनके बहुमुखी गुणों के कारण विभिन्न क्षेत्रों में किया जाता है:

धातुकर्म उद्योग: इन ईंटों का उपयोग आमतौर पर भट्टियों और भट्टियों की लाइनिंग में किया जाता है जहां उच्च तापमान और रासायनिक स्थिरता आवश्यक होती है। वे सुरक्षित संचालन सुनिश्चित करते हुए ऊर्जा दक्षता को अनुकूलित करने में मदद करते हैं।

सिरेमिक और ग्लास विनिर्माण: सिरेमिक और कांच के उत्पादन में, बबल एल्यूमिना ईंटें उत्कृष्ट इन्सुलेशन प्रदान करती हैं, समान गर्मी वितरण सुनिश्चित करती हैं और अंतिम उत्पादों में दोषों को कम करती हैं।

विद्युत उत्पादन: बबल एल्यूमिना फायर ब्रिक्स का उपयोग बिजली संयंत्रों में किया जाता है, विशेष रूप से बॉयलर अनुप्रयोगों में, जहां वे कुशल ताप प्रबंधन और ऊर्जा संरक्षण में योगदान करते हैं।

औद्योगिक ओवन और भस्मक: अत्यधिक तापमान झेलने और थर्मल झटके का विरोध करने की उनकी क्षमता उन्हें औद्योगिक ओवन और अपशिष्ट भस्मक में उपयोग के लिए आदर्श बनाती है।

जबकि मिट्टी इन्सुलेशन ईंटों का उपयोग आमतौर पर उच्च तापमान वाले वातावरण में इन्सुलेशन के लिए किया जाता है, बबल एल्यूमिना फायर ईंटें कई फायदे प्रदान करती हैं:

उच्च तापमान सहनशीलता: बबल एल्यूमिना ईंटें मानक मिट्टी इन्सुलेशन ईंटों की तुलना में काफी अधिक तापमान सहन कर सकती हैं, जो उन्हें चरम अनुप्रयोगों के लिए अधिक उपयुक्त बनाती हैं।

उन्नत इन्सुलेशन: बबल एल्यूमिना ईंटों की अनूठी सेलुलर संरचना बेहतर इन्सुलेशन प्रदान करती है, जिससे उद्योगों को ऊर्जा लागत बचाने में मदद मिलती है।

हल्का स्वभाव: बबल एल्यूमिना फायर ईंटें आमतौर पर मिट्टी की ईंटों की तुलना में हल्की होती हैं, जिससे रखरखाव और स्थापना आसान हो जाती है।

बबल एल्यूमिना फायर ईंटें दुर्दम्य सामग्रियों में एक महत्वपूर्ण प्रगति का प्रतिनिधित्व करती हैं, जो अद्वितीय थर्मल दक्षता, हल्की संरचना और रासायनिक स्थिरता प्रदान करती हैं। धातुकर्म से लेकर बिजली उत्पादन तक विभिन्न उद्योगों में उनका अनुप्रयोग उनकी बहुमुखी प्रतिभा और प्रभावशीलता को उजागर करता है। चूँकि कंपनियाँ बेहतर ऊर्जा दक्षता और परिचालन प्रदर्शन के लिए प्रयास करती हैं, बबल एल्यूमिना फायर ब्रिक्स उच्च तापमान अनुप्रयोगों के लिए एक उत्कृष्ट विकल्प प्रस्तुत करती हैं।

पर डीवाईसेन औद्योगिक, हम अपने ग्राहकों की विशिष्ट आवश्यकताओं को पूरा करने के लिए तैयार उच्च गुणवत्ता वाली बबल एल्यूमिना फायर ईंटें प्रदान करते हैं। उत्कृष्टता और ग्राहक संतुष्टि के प्रति हमारी प्रतिबद्धता यह सुनिश्चित करती है कि आपका परिचालन सुचारू और कुशलतापूर्वक चले।